Right after soldering, the board is cleaned and checked for flaws. If any is identified, the defects are repaired after which you can the products is stored.

By looking at these components, you should be able to discover an SMT pick and place machine that meets your requirements. It can be crucial to know your businesses needs and select tools that fulfills the vast majority of those requirements.

After SMCs are placed, the PCB is then conveyed to the reflow soldering oven, where it passes by the subsequent zones to endure the soldering procedure:

An SMT pick and place machine is actually a specialised piece of equipment created to automate the placement of Digital components on to printed circuit boards (PCBs). Making use of Superior robotics and complicated eyesight programs, these machines can quickly and accurately placement factors, like resistors, capacitors, and integrated circuits, in a seamless workflow.

As a typical part of SMT machines, a variety of issues might crop up in the course of operation, such as The shortcoming to pick up, place, or install in the incorrect situation. So let's talk about the reasons and solutions for element extraction faults.

This chip mounter machine delivers exceptional adaptability in element dealing with. It could possibly accommodate a variety of part dimensions and kinds, from compact components to intricate QFPs and BGAs, guaranteeing specific placement for varied generation requires.

Lowered Downtime: Pick and place machines can function consistently with no breaks and have small set up time involving output operates. This minimizes downtime and retains the producing procedure working easily and successfully.

SMDs make for devices developed more quickly, with a lot more adaptability and less Expense, without sacrificing operation. They guarantee a lot more functionality because scaled-down elements allow For additional circuits on little board House. This miniaturization is the most important characteristic of SMD.[six]

They Look at the particular placement Along with the meant placement depending on the program. If any discrepancies or misalignments are detected, the system may make true-time adjustments to ensure specific placement.

Our aid group have all worked as procedure engineers Performing in SMT-manufacture and may advise dependant on true environment practical experience. Simply call us now to discuss your requirement.

The SMT placement machine is also referred to as the placement machine. The placement machine is really a complex comprehensive products made up of a rack, a transmission technique, a eyesight method, a computer software and hardware. The placement machine is accustomed to mount electronic components into a PCB (circuit board) During the Digital processing gear, the densely packed electronic elements on the motherboard inside the Digital tools utilized are all made by the placement machine and afterwards reflow soldering.

As soon as the in line pick and place machine is set up, it might Make PCB’s in a “arms-no cost” mode with bare PCB’s transported in the machine automatically and once all elements are placed they thoroughly assembled PCB transports out into another phase of assembly, This is certainly either automatic Visible inspection or straight right into a reflow oven where by all elements are soldered into place.

Each Neoden United states merchandise includes a regular a person 12 months warranty that pick and place machine includes components and specialized help (extendable). Our engineers are US based mostly and able to walk you through any troubles chances are you'll come upon, and we have been generally accessible to assist you to with First set up and setup of the machines.

Ease of PCB assembly, applying each side of your board without the gap limits that exist in the traditional process

Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Sam Woods Then & Now!

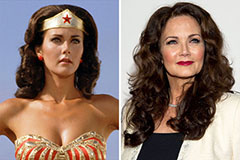

Sam Woods Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!